Sustainability Report 2024

Sustainability is not just a trend; it is of great importance for our customers, employees, and the public.

Our customers’ expectations and needs are also at the forefront of our sustainability journey and the ongoing development of our product portfolio: After all, sustainability is a key factor in securing the long-term success of our company.

Sustainability Strategy

In the 40 years since our founding, we have already reached significant milestones in sustainable development. We have also established ambitious targets for the future.

Schattdecor is currently developing a clear ESG strategy:

Based on our materiality assessment and preparations for the CSRD, we first evaluated the current status of various sustainability issues within our company. The next step involves defining targets and measures to address strategic topics.

Publication of our first sustainability report for the Schattdecor Group. Our aim is to create greater transparency and demonstrate our sustainability commitment to our stakeholders.

Interview with Ana Pamplona

Ana Pamplona has been working at our Brazilian locations in Marketing and Communications since 2021. In 2024, she also took on the role of Sustainability Manager for São José dos Pinhais, Brazil. In Ana’s view, this is both a privilege and a significant responsibility, which she embraces with her communication and networking skills, tackling even complex topics without hesitation.

What does sustainability management look like at Schattdecor?

"Environmental and social sustainability have always been a core principle of our company. Due to increasing demands and requirements, including those from regulatory bodies, we now

need a Group-wide governance structure. I’m particularly enthusiastic about our young, interdisciplinary team of sustainability managers. We come from all over the world and share the

same passion for the topic. Since our first networking meeting, we’ve been working together as a group, guided and supported by the team in Thansau. This makes every task easier, and I’m

confident our sustainability management will quickly achieve global success!"

You can find the full interview with Ana in the Sustainability Report on page 16.

Climate Change & Engergy

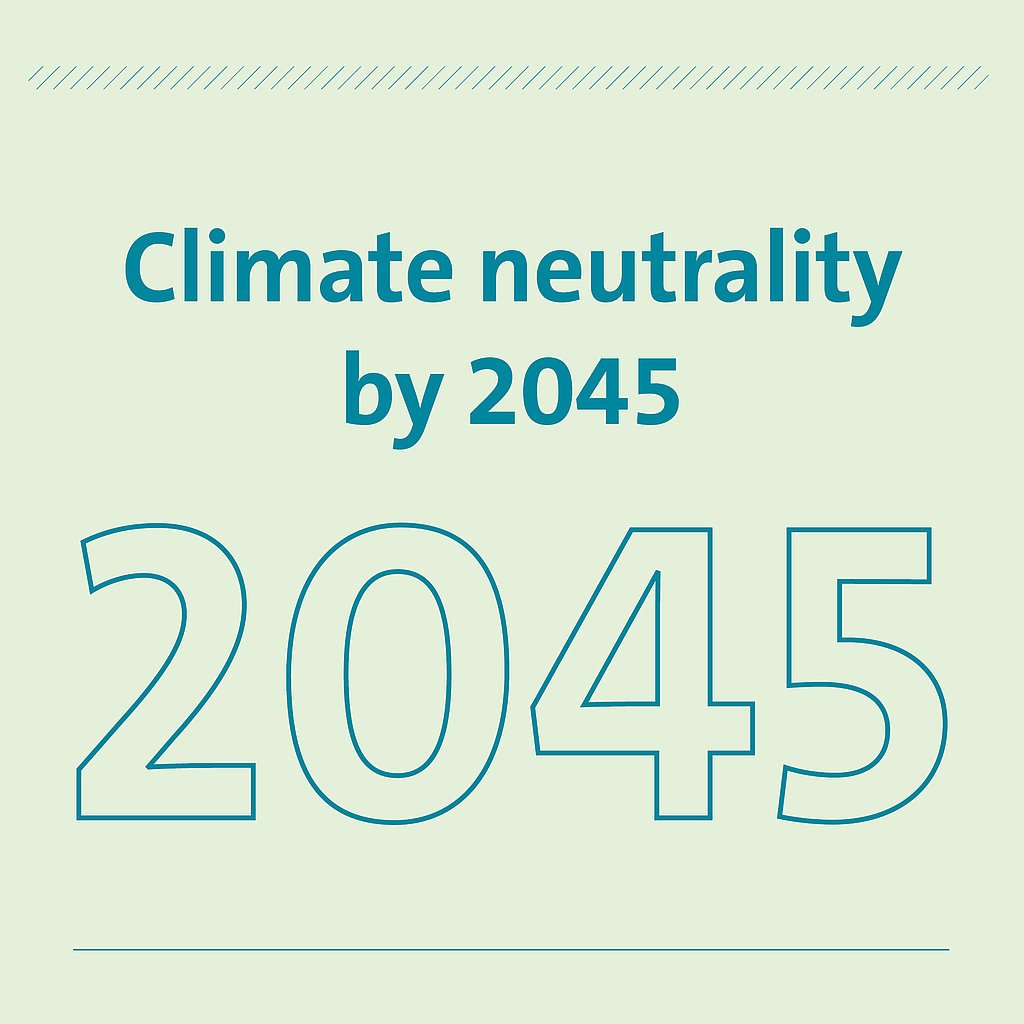

Our Goal: Net-Zero Greenhouse Gas Emissions

No aspect of environmental protection presents a greater challenge to our economy than addressing climate change. Therefore, decarbonization and achieving climate neutrality by 2045 are central to our sustainability strategy.

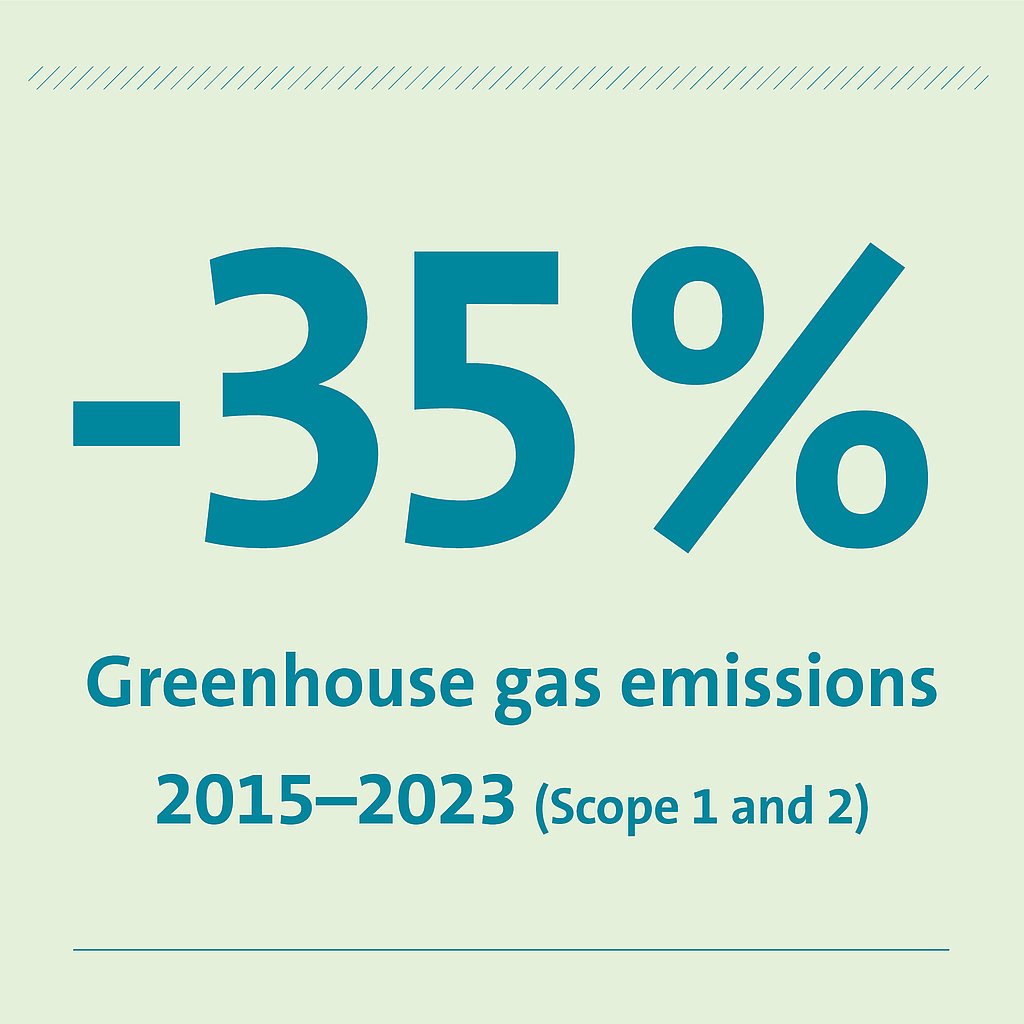

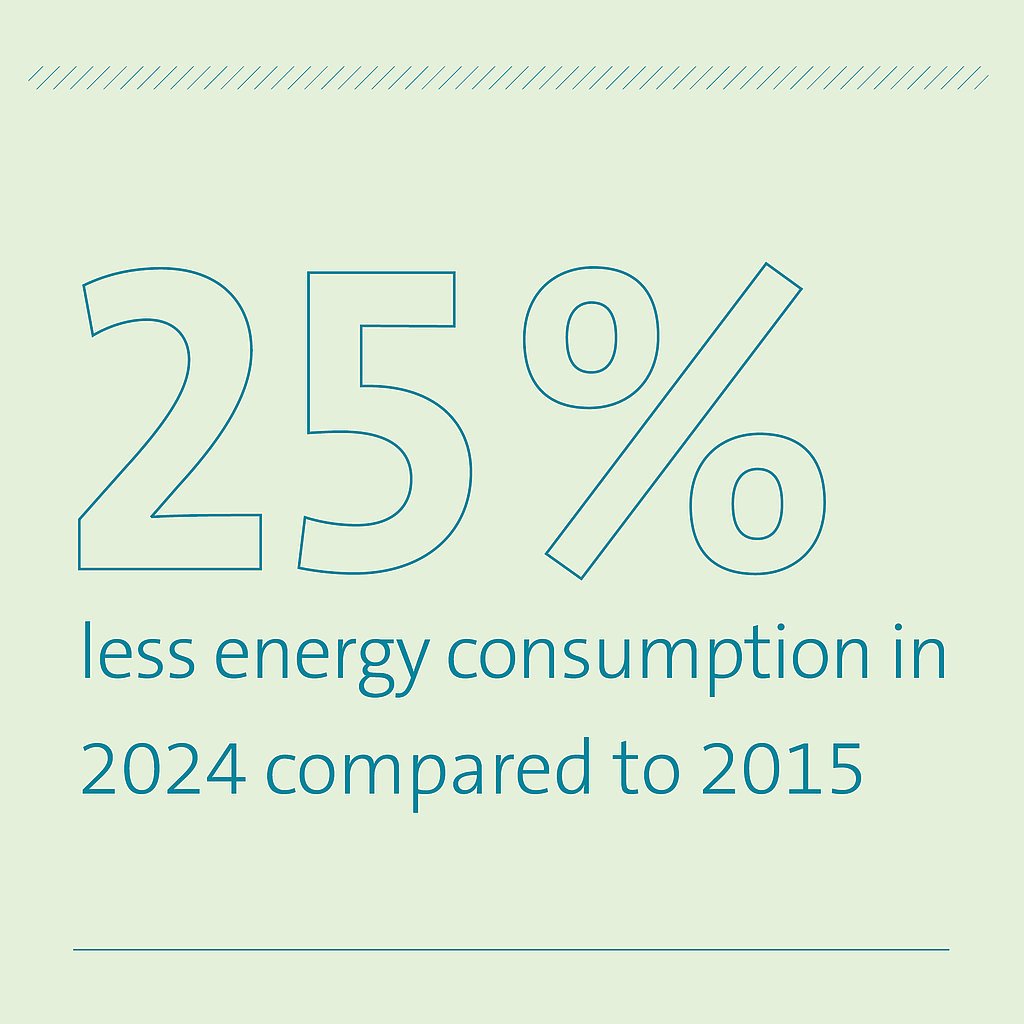

The Schattdecor Group has set itself an ambitious target: climate neutrality by 2045. An important milestone in achieving this goal is the reduction of direct greenhouse gas (GHG) emissions from our own facilities, as well as indirect emissions from purchased energy, by 35% by 2030.

Interview with Mariusz Bączek

Mariusz Bączek has been an integral member of the Schattdecor family since 2007. After joining the company in the production department, he has been working at the Tarnowo

Podgórne site since 2016 as a technical and technological projects coordinator, as well as an energy and environmental manager.

What specific measures impact climate protection and energy efficiency?

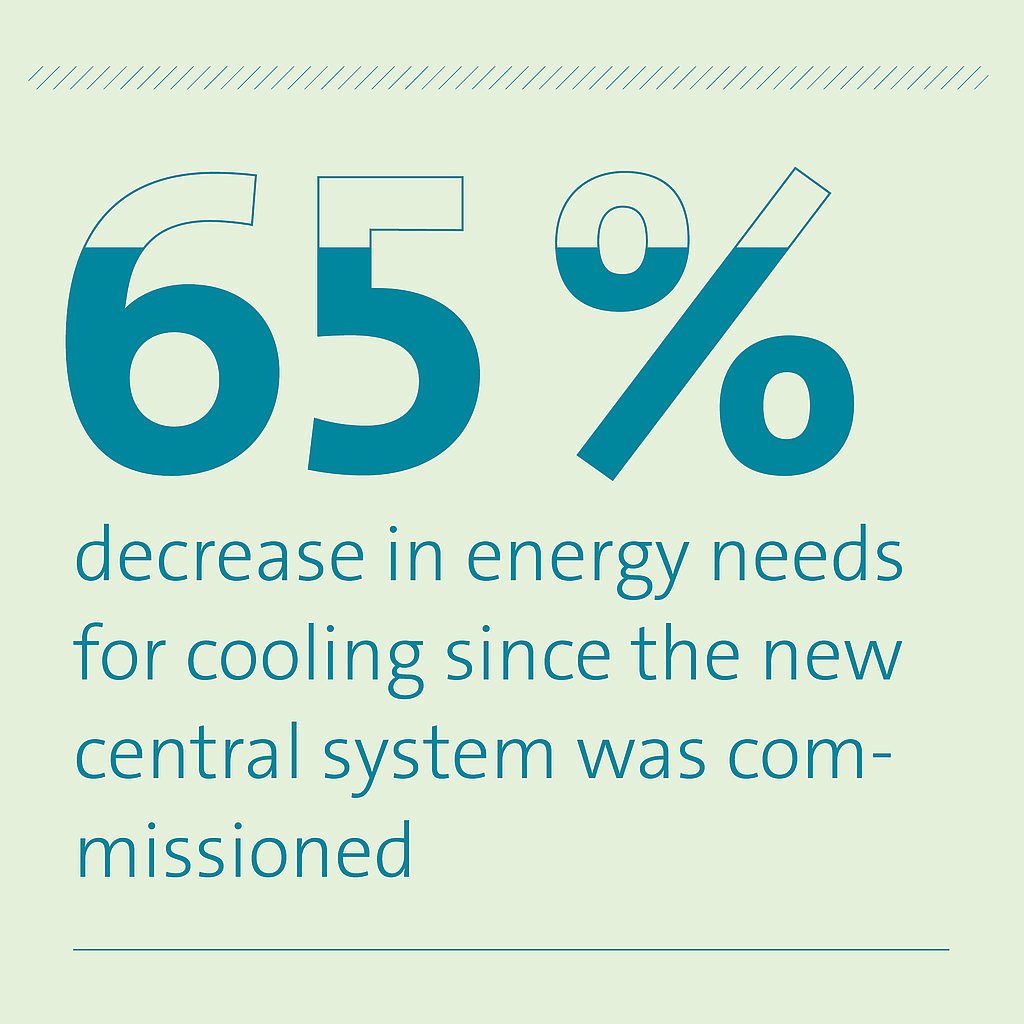

"It starts with the sustainable use of everyday building technology such as heating, lighting, and air conditioning systems. Switching to LED technology or installing presence sensors makes a big difference. Other measures require technical expertise, for example, the further development of our paper humidification system. It now operates completely without energy-intensive steam generation. We have also developed a separate cooling system that, through central control, completely eliminates redundant chillers and is also extremely economical thanks to an intelligent weekend standby mode. Moreover, a significant milestone was the signing of a 10-year power purchase agreement that guarantees our supply of green electricity."

You can find the full interview with Mariusz in the Sustainability Report on page 23.

Decarbonization at Schattdecor

We are tackling decarbonization at Schattdecor in three areas: energy efficiency, technical and technological innovations, and using resources that meet even higher sustainability standards.

Energy Efficiency

Our new administration building in Thansau is certified with the highest energy efficiency class EG 40-EE and features an innovative climate control and heating concept. After being used in the office spaces, the warm air is additionally directed into our atrium. From there, it’s vented outside through the heat exchanger. This shows how, in Thansau, targeted innovation, responsible conservation measures, and forward-thinking design interlock to decarbonize our operations.

Technical and technological innovations

An outstanding example of process optimization is the further development of our drying process. During the printing and impregnation process, the surfaces are in a moist state and must be dried in a controlled manner for further processing. The heaters used for this have so far operated most efficiently with gas. Several years ago, we were able to reduce the gas consumption of the printing press dryers significantly. Building on this success, the concept was transferred to the impregnation process. Through targeted retrofitting of the impregnation systems at our Italian site, the same drying result could be achieved with 20% less gas consumption. This optimization has proven successful and has already been implemented at other international locations, including Malaysia and Brazil.

Using resources

We have fundamentally revised the heating supply in Thansau, transitioning to a central heating system in 2024. This represents an important step for Schattdecor towards independence from fossil fuels. Instead of gas heating systems, we are gradually converting our heat generation to wood pellets. Moreover, infrastructural preparations have already been made for potential use with biogas, green hydrogen, or full electrification with green electricity.

Circular Economy

High-Quality Surfaces – Produced with Resource Efficiency

The primary raw material for our surfaces is decor paper, which consists predominantly of cellulose. This is mainly obtained from wood, a renewable resource.

Today, our PP-based thermoplastic foils are already free of environmentally harmful and health-damaging plasticizers, chlorine, and solvents. Looking ahead, the goal is to replace conventional, petroleum-based raw materials with recyclates or biobased and biodegradable plastics.

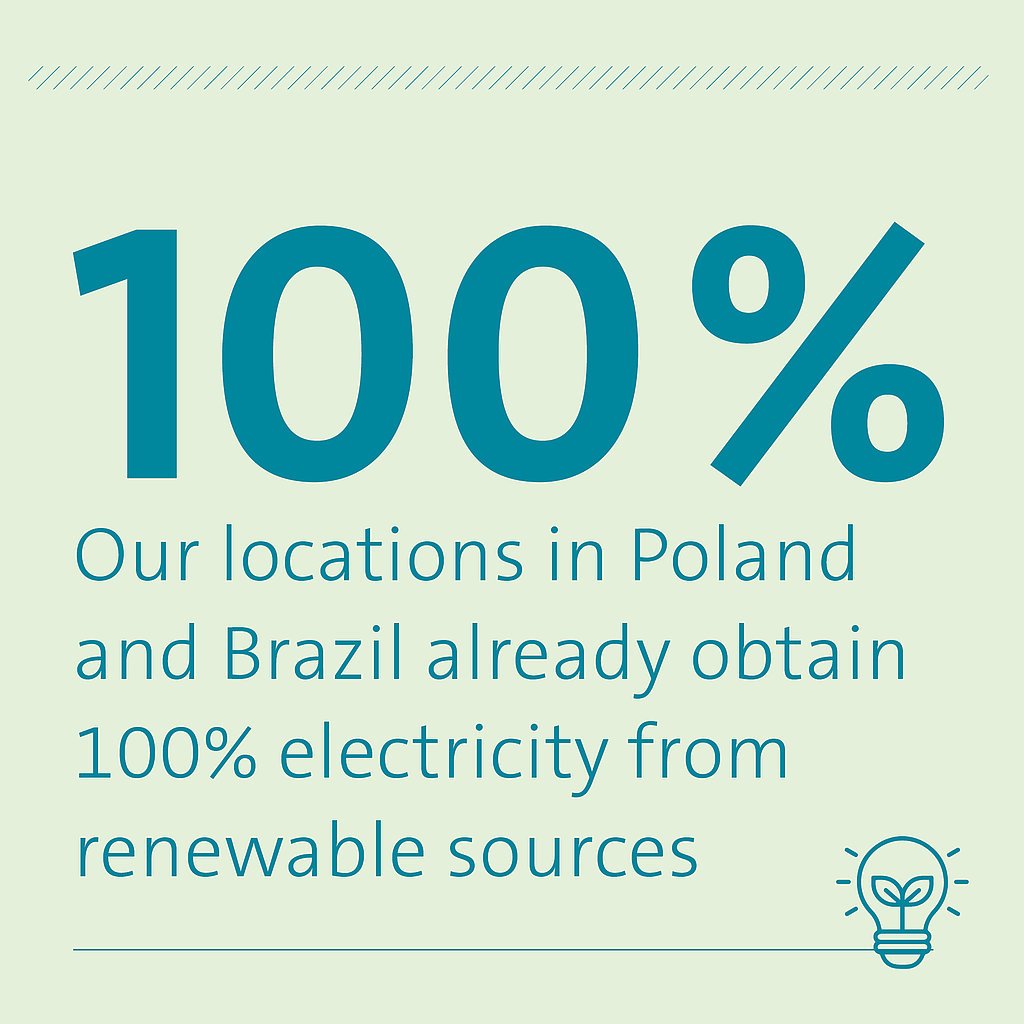

This approach allows us to increasingly close material loops. Since the drying of thermoplastics requires less heat than paper, we can fully electrify the production of our PP, PVC, and PET foils and thus eliminate the need for fossil fuels: From the so-called extrusion of the plastic granules to decor printing and finishing, electricity from renewable sources can be used.

Schattdecor operates responsibly worldwide in accordance with FSC requirements. This means, for example, that old-growth forests are protected from industrial logging, core labor standards are observed within the company, and the rights of indigenous peoples are upheld.

Interview with Sophia Mayerhofer

As a native of Upper Bavaria, Sophia Mayerhofer first encountered her current employer during a company tour as a student. After studying plastics engineering and working in the automotive industry, Sophia began her career at Schattdecor in 2019 as a development engineer in the Research and Future Technologies department. She has led this department since the summer

of 2023.

What topics are currently the focus of your Research and Future Technologies department?

"My team and I are engaged in the development of promising future materials and the processes for working with these new materials. A particular focus is currently on the development of thermoplastic substrates and their further processing. Thermoplastics are a subgroup of plastics and, as printable foils, could represent a very promising substrate for our surfaces in addition

to paper."

What properties of thermoplastics are you and your team currently exploring?

"While thermoplastics, as plastics, are petroleum-based, their production is less water- and energy-intensive than that of paper. Furthermore, after thermoplastics are printed as substrates at Schattdecor, they require less heat energy for drying than paper substrates. That’s why we can fully electrify previously natural gas-based drying processes. If we then source our energy

entirely from renewable sources, as is already the case in our Polish plants, our emissions will be reduced.

You can find the full interview with Sophia in the Sustainability Report on page 36.

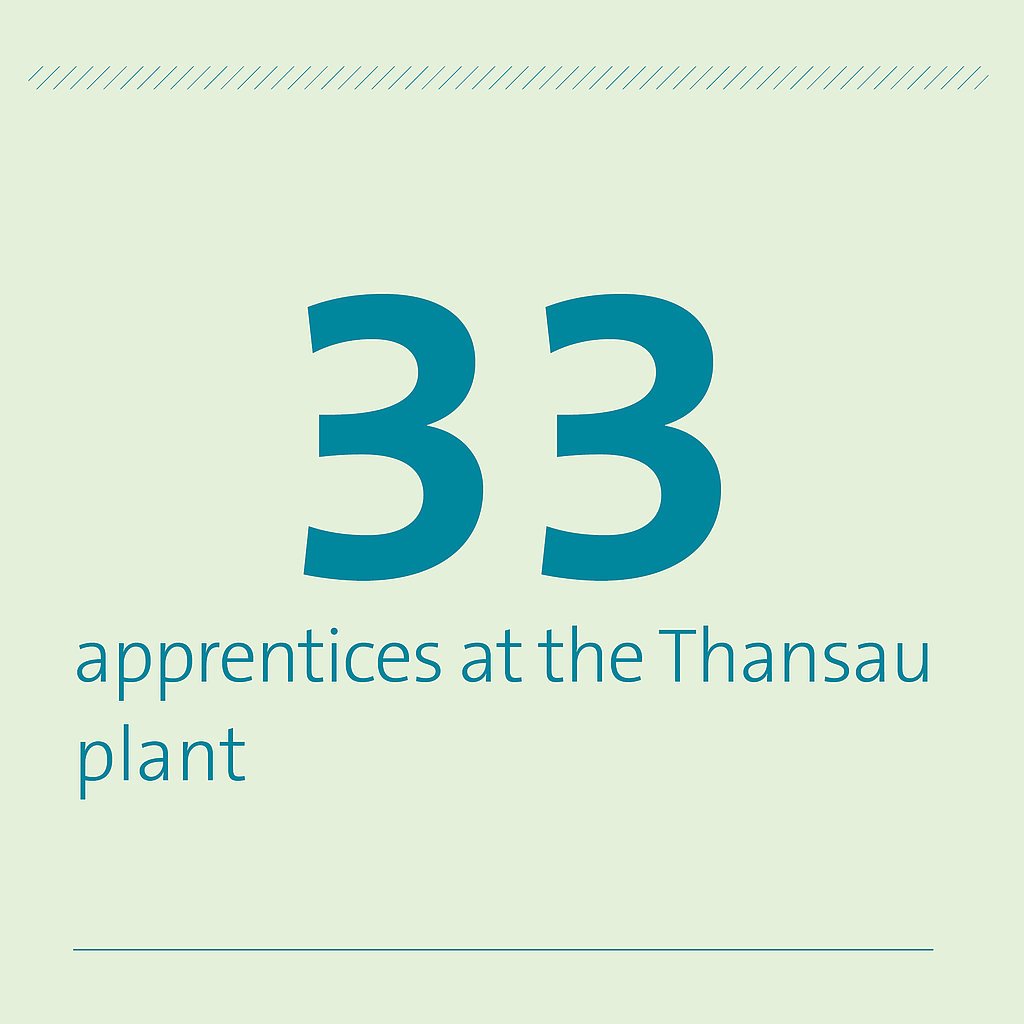

Valuing People

“You have to like people” - this is how Walter Schatt summarized his philosophy of employee management. We still adhere to this principle today, because our company's success is inextricably linked to our quality as an employer.

All 16 locations provide our employees with a safe, supportive workplace that respects the local culture. At the same time, we maintain close ties with our headquarters in Germany. It’s not unusual to hear our international colleagues greet each other with a Bavarian “Servus!”.

Since Schattdecor’s founding, sustainability has been an integral part of our corporate philosophy. Today, it remains a steadfast component of the company’s fabric and leadership. Ultimately, it is our employees’ commitment and enthusiasm that bring sustainability to life.

EcoTeam at Schattdecor Poland: Together for a Greener Future

One example of active participation in the topic of sustainability is the EcoTeam, an employee initiative of Schattdecor Poland with the aim of promoting environmental protection and education. Employees are encouraged to contribute ideas, which are subsequently developed collaboratively and integrated into the company.

Practical examples:

- Setting up compost bins for waste

- Using notebooks made from old stationery

- Reducing plastic consumption and eliminating paper cups

- Sustaining a water conservation campaign

- Selecting air-purifying plants for offices

- Building insect hotels and nesting boxes for swifts

- Reforestation projects

- Promoting the “Keep the Planet Clean” initiative on Earth Day

- Implementing the “Switch Off the Lights” energy-saving initiative

- Promoting health in everyday life

Our social responsibility

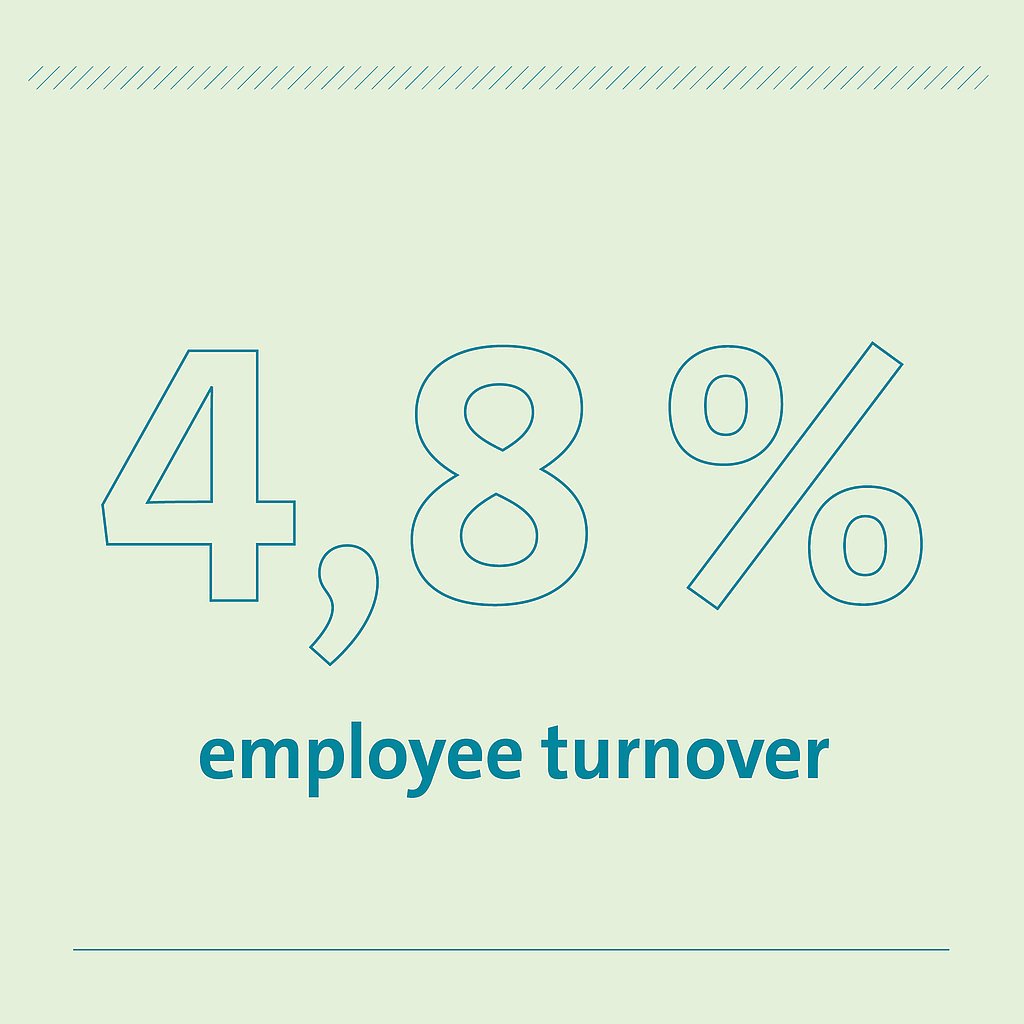

Schattdecor as an employer

Entrepreneurial courage and trusting collaboration within the international workforce allowed the company to grow under Walter Schatt. These values continue to make us an economically successful and reliable employer today.

Interview with Hu Dong

Hu Dong came to Germany as a student in printing technology and joined us as a trainee in 2013 after completing his master’s degree. In 2015, he returned to his home country with Schattdecor, initially to Shanghai, then to Quzhou, where he is now factory manager and energy and environmental manager.

How do you perceive the company culture?

"Schattdecor is an employer that takes excellent care of its employees. That’s one reason why I can very well imagine retiring at Schattdecor! From the very first day, I felt welcome here – professionally and beyond. I still remember clearly when I was a new trainee in Thansau, some colleagues took me along to play sports after work. This open and warm nature is particularly valuable for new employees from abroad."

You can find the full interview with Hu in the Sustainability Report on page 44.