Technical impregnated products

With our Teclay product line, we provide you with special technical melamine films: overlays, underlays, and backing papers. Although these do not provide a visual feature, they offer significant added value for the technical construction of flooring and furniture panels. As part of Teclay, we also offer solutions for coating and finishing plywood panels.

The optimum protective layer - Teclay Overlay

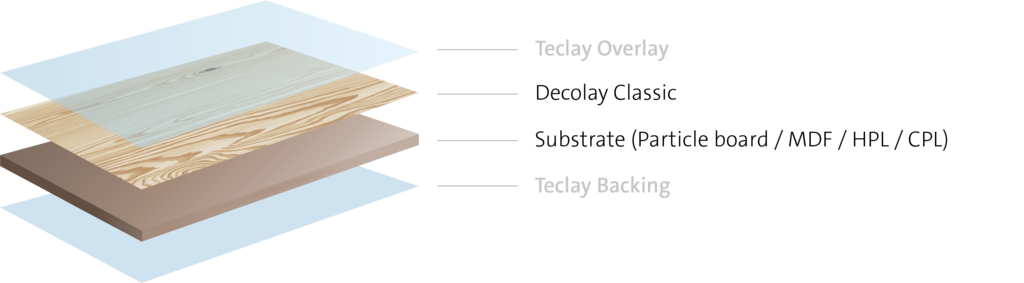

Teclay Overlay is the ideal complement to our classic impregnated product Decolay Classic. As a wear layer, it protects the decorative film and provides an abrasion-resistant coating for your wood-based materials. We manufacture our overlay papers from cellulose paper treated with amino plastics and additives, with or without mineral corundum. The pigment- and filler-free melamine film becomes completely transparent when pressed.

Tension equalizing - Teclay Backing

With Teclay Backing, we offer impregnated backing papers that are required for high-quality coating of wood-based materials in the furniture and flooring industry. Used on the underside of laminate panels, Teclay Backing is primarily responsible for equalizing the tension with the overlay and decorative paper on the top.

The combination of our overlay, our Decolay Classic impregnate, and our backing also results in a high-quality package solution for the flooring industry!

Teclay Overlay and Teclay Backing are used in the furniture, countertop, and above all in the flooring sector as LPL, HPL, DPL, or CPL bonding.

Application example

Levels irregularities - Teclay Underlay

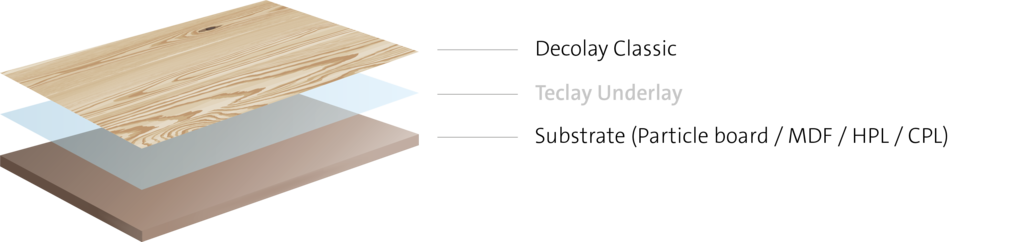

Teclay Underlay makes it possible to level out any unevenness on substrate materials. The product increases the opacity of the melamine film and thus prevents the nature of the substrate from influencing the final visual result. In addition to achieving uniform, brilliant surfaces, Teclay Underlay can also be used as a base to achieve greater structural depths.

Teclay Underlay is used in the furniture and interior design sectors as well as for countertops such as LPL, HPL, or CPL bonding.

Application example

Finishing of plywood - Teclay Recoat

Teclay Recoat provides you with new possibilities for coating or finishing plywood panels as substrate materials. The interaction of two components creates the optimum primer film: while the melamine backcoat as the bottom layer guarantees adhesion to the plywood panel, the top layer prepares the material ideally for further processing by the customer - for example, for overcoating or for a paint application.

From interior fittings and renovations to outdoor playground equipment: Teclay Recoat opens a wide range of possible applications within indoor and outdoor scenarios. We can produce our technical melamine films (Teclay) with variable film weights and a production width of up to 2,800 mm. The products in the line are available in sheets or rolls.

Product structure

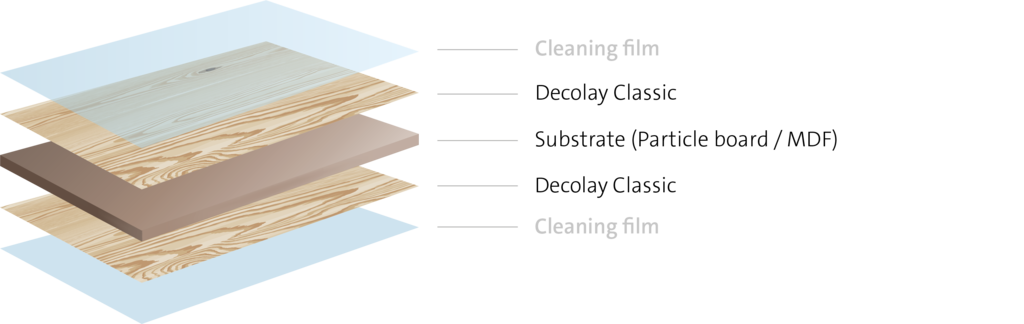

Effective Cleaning Solution for Press Plates – Teclay Cleaning

Teclay Cleaning is the efficient and particularly user-friendly solution for thorough cleaning of short-cycle press plates and continuous double-belt presses (CPL-presses)—developed based on specific market requirements.

The cleaning film reliably removes even stubborn dirt and deposits without the need to remove the press plates during the pressing process. Teclay Cleaning thus supports smooth machine operation, reduces downtime, and actively contributes to time- and cost-efficient process optimization—for consistently high surface quality of your pressed panels.

Your advantages at a glance:

Deep cleaning during the pressing process

Removal of the press plates is not necessary

Improvement of fine and deep structures

Optimized heat transfer to the decorative surface

Material is available in sheets or rolls

Can be stored for over 12 months

Application example

Optimal Release Film for Press Plates – Teclay Conditioning

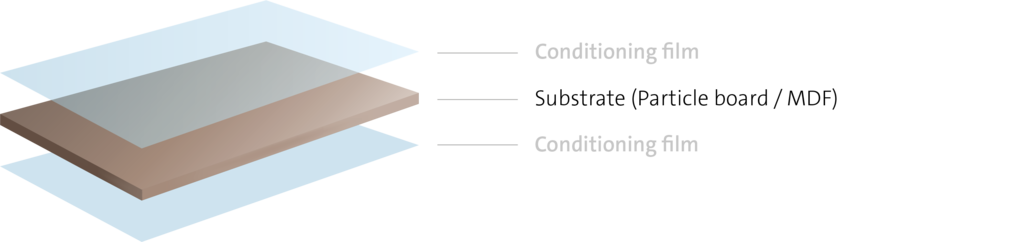

Teclay Conditioning is a specially developed film that ensures the boards will detach cleanly and without residue from the press plate after the first pressing. This will lay the foundation for smooth, economical, and high-quality production.

In addition, Teclay Conditioning reliably protects the surface of the press plate from new deposits and contamination—ensuring a reliable release of the board with deep structures or special matte effects.

Your advantages at a glance:

Removal of contamination

Protection against new deposits

(Re)establishment of optimal press plate condition

Integration into the ongoing production process

Material is available in sheets or rolls

Can be stored for over 6 months

Application example

Would you like to find out more about our technical impregnated products? Please contact us!

Contact person worldwide

Dieter Schuckmann | Head of Sales Impregnation

Phone: +49 8031 275 – 2288

d.schuckmann@schattdecor.de

Contact person USA

Claire Froschauer I North American Sales Manager (USA)

Phone: +1 314 400-6111

c.froschauer@schattdecor.us